- 83 reads

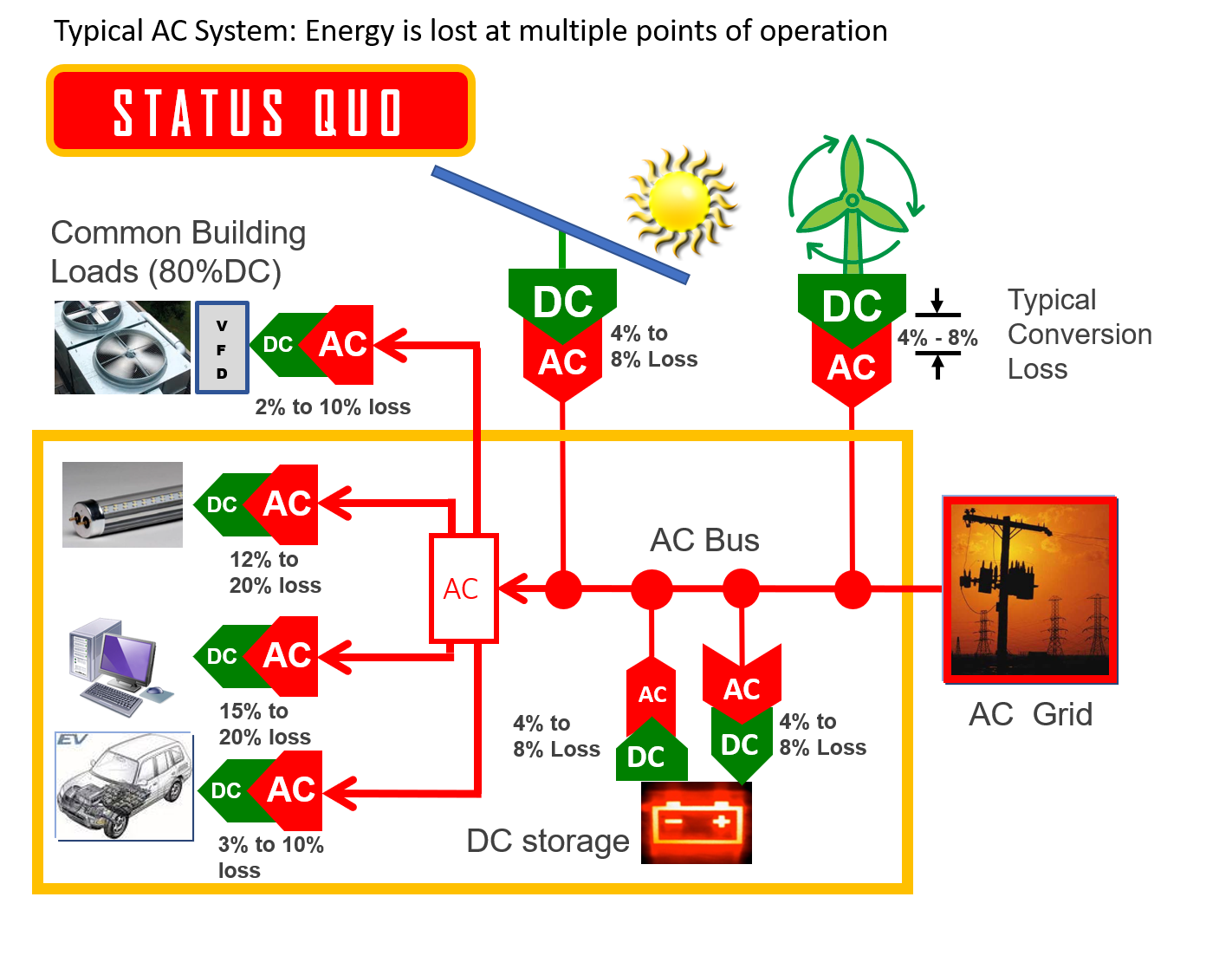

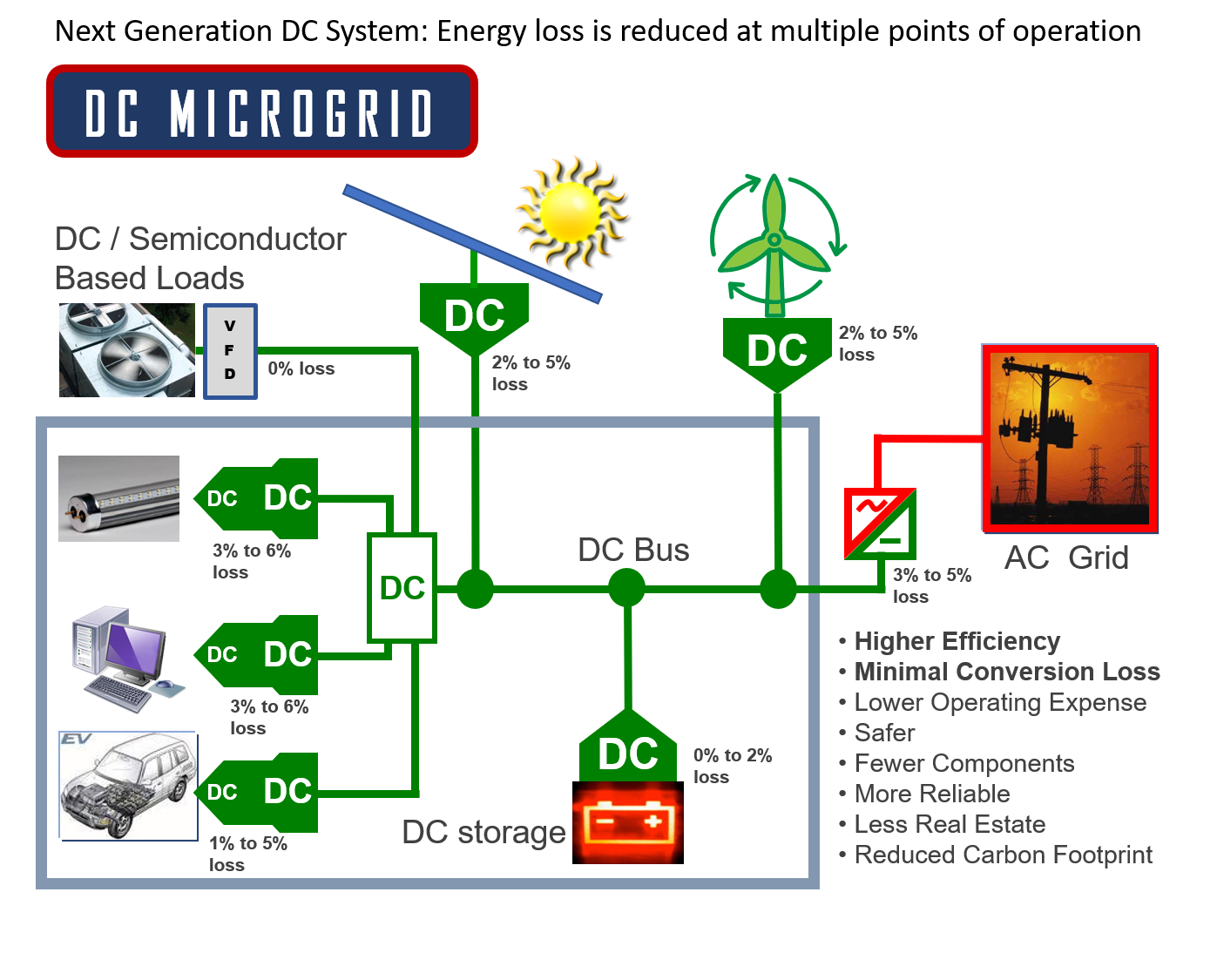

While Alternating Current (AC) is still the most efficient means to move electricity over long distances “local” power inside of facilities wastes less electricity with DC Microgrids.

You might be surprised if you look up at the ceiling and and start to see lighting fixtures that are powered by direct current (DC).

A leading US LED manufacturer, Independence LED Lighting (www.independenceled.com/dc-microgrids), developed its first Direct Current (DC) powered LED fixture series in 2015 for an industrial facility. Their DC LED fixtures are “driverless” with 24 volt DC wiring from a “Power hub Driver” (PhD), which is provided by their strategic partner Nextek Power Systems (www.Nextekpower.com). Together, they are at the forefront of DC Microgrid technology, with the proven systems that leverage high efficiency power converters and smart controls to optimize energy usage while drawing power from renewables, batteries, and/or the grid. The technology reduces the payback time for lighting ROIs and improves control functionality, yielding the most practical solution for powering LEDs for facilities across the public and private sector.

Energy Use for Lighting:

Loss with AC: 12%-20% (avg 16%)

Loss with DC: 3%-6% (avg 4.5%)

Avg Net SAVINGS with DC: 11.5%

Energy Use for Computers:

Loss with AC: 15% -20% (avg 17.5%)

Loss with DC: 3%-6% (avg 4.5%)

Avg Net SAVINGS with DC: 13%

Plus: The Air Conditioning savings is 6% and the savings for Electrical Vehicle Charging stations is 3.5%

TOTAL: 34%

Lighting typically accounts for 25% of energy use, and LEDs cut the consumptions by 50%. This translates into a net 12.5% reduction in total energy costs.

Lighting is typically the “low hanging fruit” of energy efficiency.

12.5% savings with lighting plus the added 34% savings with DC power

GRAND TOTAL = 46.5% facility energy savings

DC based power distribution, lighting, and controls technology offers the most efficient use of energy available. For the Independence LED Lighting / Nextek system, this is achieved by eliminating the traditional LED ‘driver’ in each fixture and replacing it with a centralized “Power hub Driver” that provides control and fixture power at a higher efficiency than any stand-alone driver. This approach also saves significant maintenance cost over time since drivers typically require replacement long before the LED chips are spent.

Results:

A significantly improved Total Cost of Ownership (TCO). Beyond the driverless approach, use of safe-to-the-touch Class 2 wiring allows for a much more simplified labor installation as compared to traditional AC methods. Use of simple 2 conductor wire can be installed with Low-Volt or General Trades labor resources.

Added labor advantage:

Facility owners and managers save both time and hourly rate costs, as compared to traditional electrical labor.

Added integration advantage:

By establishing a DC microgrid based backbone to power lighting, controls and other loads, it can be easier to connect additional power sources to the DC buss such as Photovoltaic (PV) solar, DC power from wind driven generators, fuel cell generators or all 3 renewable sources. By basic engineering of DC voltage performance, a DC bus can be very effectively managed. Accomplishing the same with AC technology would require use of less reliable inverters that then require phase management to work with other systems.